Leveraging Outsourced Manufacturing to Scale Operations Quickly in Government Contracting

Use all of your facilities and Resources.

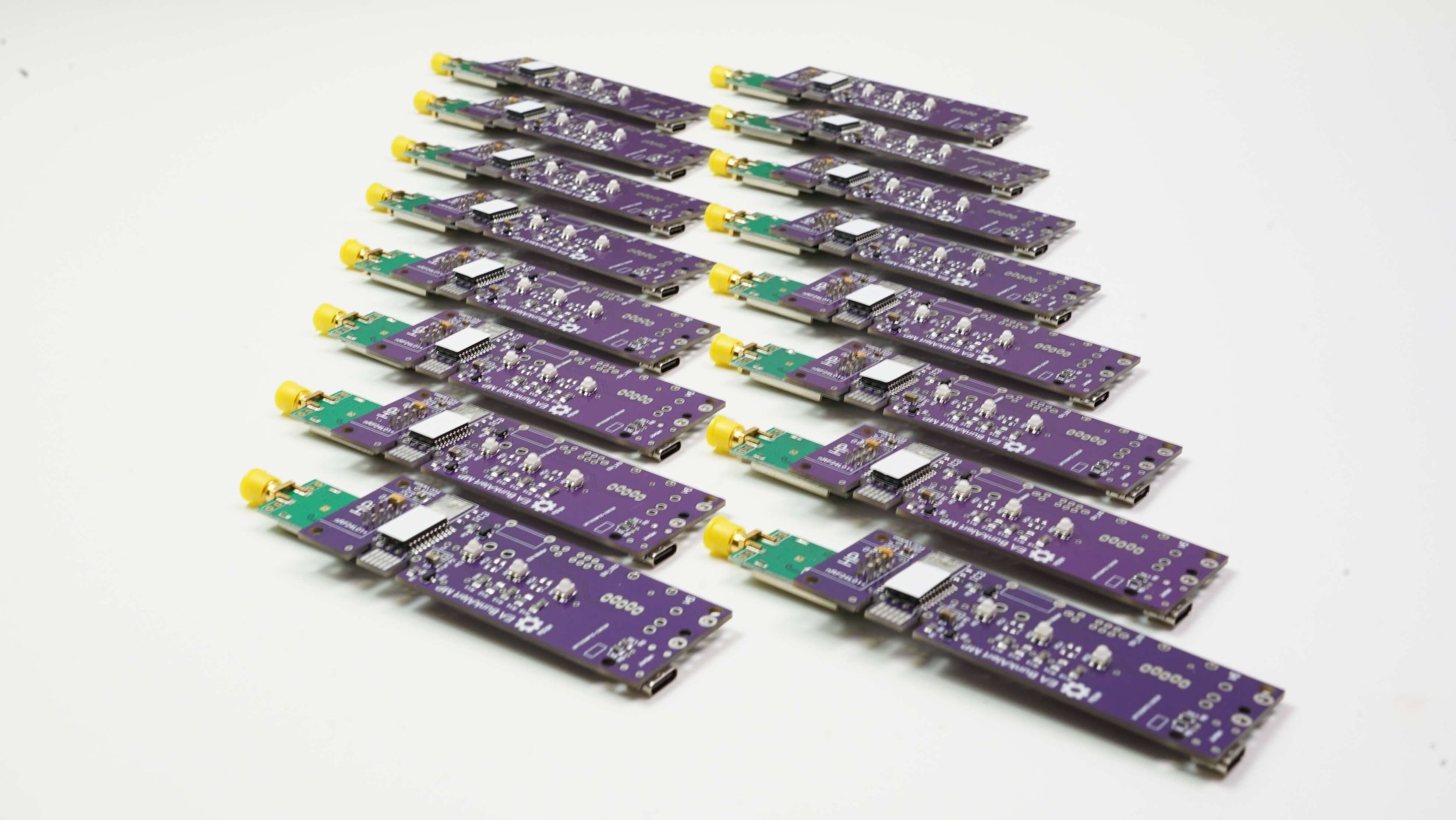

For those in leadership roles at engineering firms like RDM Innovation, scaling operations to meet the demands of government contracts or subcontracts can be both exhilarating and challenging. Here at RDM, we understand the intricacies of this balance. This blog post will guide you through utilizing outsourced manufacturing to accelerate your project timelines, enhance product quality, and maintain compliance—all while keeping assembly in-house to retain control over the final product. We'll explore practical examples, discuss essential tools like go-no go gauges, and address regulatory considerations pertinent to government work.

Understanding Outsourced Manufacturing for Scaling

Strategic Outsourcing for Parts:

Scenario 1: Ready Design Files - If your designs are finalized, outsourcing parts production can significantly speed up your timeline. At RDM, we recommend selecting vendors with expertise in government specifications or standards such as MIL-STD, ISO, or ASME. For example, when producing components for a military application, you'd want a manufacturer adept at handling military-grade materials and adhering to stringent specifications.

Scenario 2: Design Not Fully Developed - When designs are still evolving, partnering with a vendor offering both manufacturing and engineering services can be a game-changer. This approach not only speeds up the process but ensures parts are designed with manufacturability in mind. RDM has leveraged such partnerships to refine and produce complex parts for government projects, ensuring they meet both functional and budgetary goals.

Tools and Fixtures for Assembly:

Go-No Go Gauges: Essential for quality control, especially in assembly where precision is non-negotiable. For instance, at RDM, we use these gauges to ensure every part of a medical device or aerospace component conforms to exacting standards before assembly.

Jigs and Fixtures: Custom jigs can streamline assembly, significantly reducing setup times and ensuring consistency. RDM has invested in these for our projects, allowing for quicker, more accurate assembly of government-contracted products.

Regulatory Considerations:

Compliance with Standards: Choosing a parts vendor involves ensuring they understand government contract requirements. At RDM, we vet our vendors for certifications like ISO 9001 or AS9100, crucial for aerospace or medical projects.

ITAR Compliance: Dealing with defense products means ITAR compliance is a must. We ensure our vendors can manage sensitive data securely, a practice we've embedded in our operations to safeguard our clients' information.

Inspection and Traceability: Government contracts often demand rigorous traceability. RDM uses ERP systems to track parts from raw material to final product, ensuring every step meets the required standards.

Practical Examples from RDM:

Case Study - Medical Device: RDM managed a government contract for a new medical device by outsourcing the production of complex plastic components but retaining assembly. We used go-no go gauges to verify part dimensions, ensuring compliance with medical regulations.

Aerospace Subcontractor: For an aerospace project, RDM outsourced part fabrication to a NADCAP-accredited supplier. Custom fixtures were developed in-house for assembly, which not only sped up the process but also guaranteed that each assembly met the prime contractor's stringent standards.

At RDM Innovation, we've seen firsthand how outsourcing manufacturing for parts while keeping assembly in-house can be a strategic move for scaling operations under government contracts. This method not only accelerates production but also maintains the quality and compliance you need. When selecting vendors, consider their industry expertise, their ability to integrate with your design process, and their compliance with regulations. With the right tools and a strategic approach, you can enhance your company's capability to deliver on government contracts efficiently and effectively.

If you're looking to scale your government contracting operations or need guidance on outsourcing manufacturing, contact RDM Innovation today. Let’s discuss how we can bring your project to life with precision, speed, and compliance. Contact Us to learn more or to get started on your next project.