Low Rate Initial Production.

At RDM, we understand that moving from prototype to production is a critical step in product development. Our Low Rate Production (LRP) services are designed to bridge that gap, offering you the ability to produce small batches that maintain the quality and precision of your prototypes. We cater to government contractors, tech startups, and established corporations looking to validate market fit, refine manufacturing processes, or simply scale up from prototyping before committing to high-volume production.

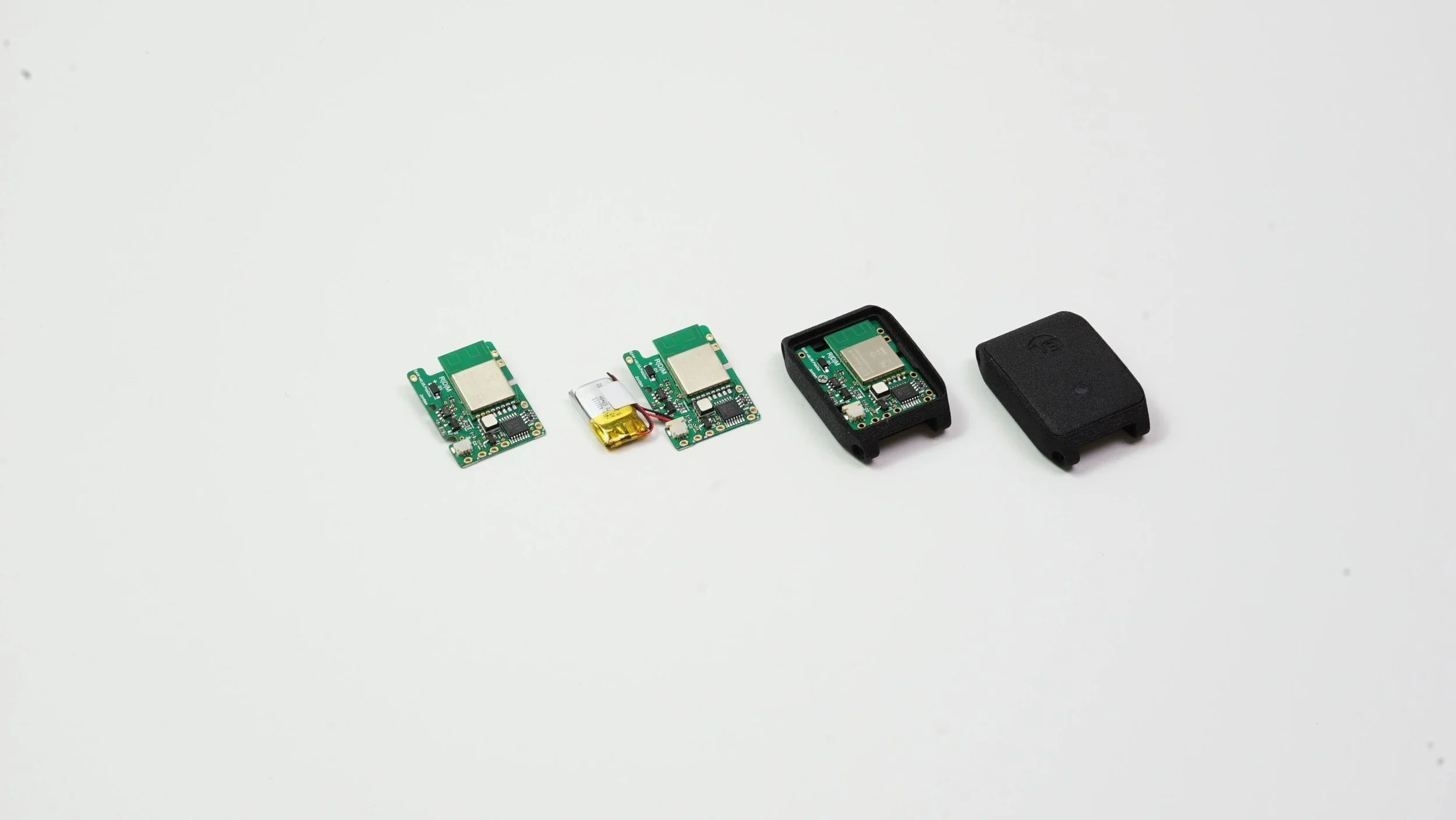

Bridging the Gap Between Prototype and Production

-

From BOM to Build

We take your Bill of Materials (BOM) and production orders, transforming them into tangible products with the same precision and care as during development. Our process ensures that every component specified is sourced and assembled correctly. We adapt our manufacturing processes, material selection, and quality controls based on the unique requirements of your product, ensuring that every batch reflects your standards.

-

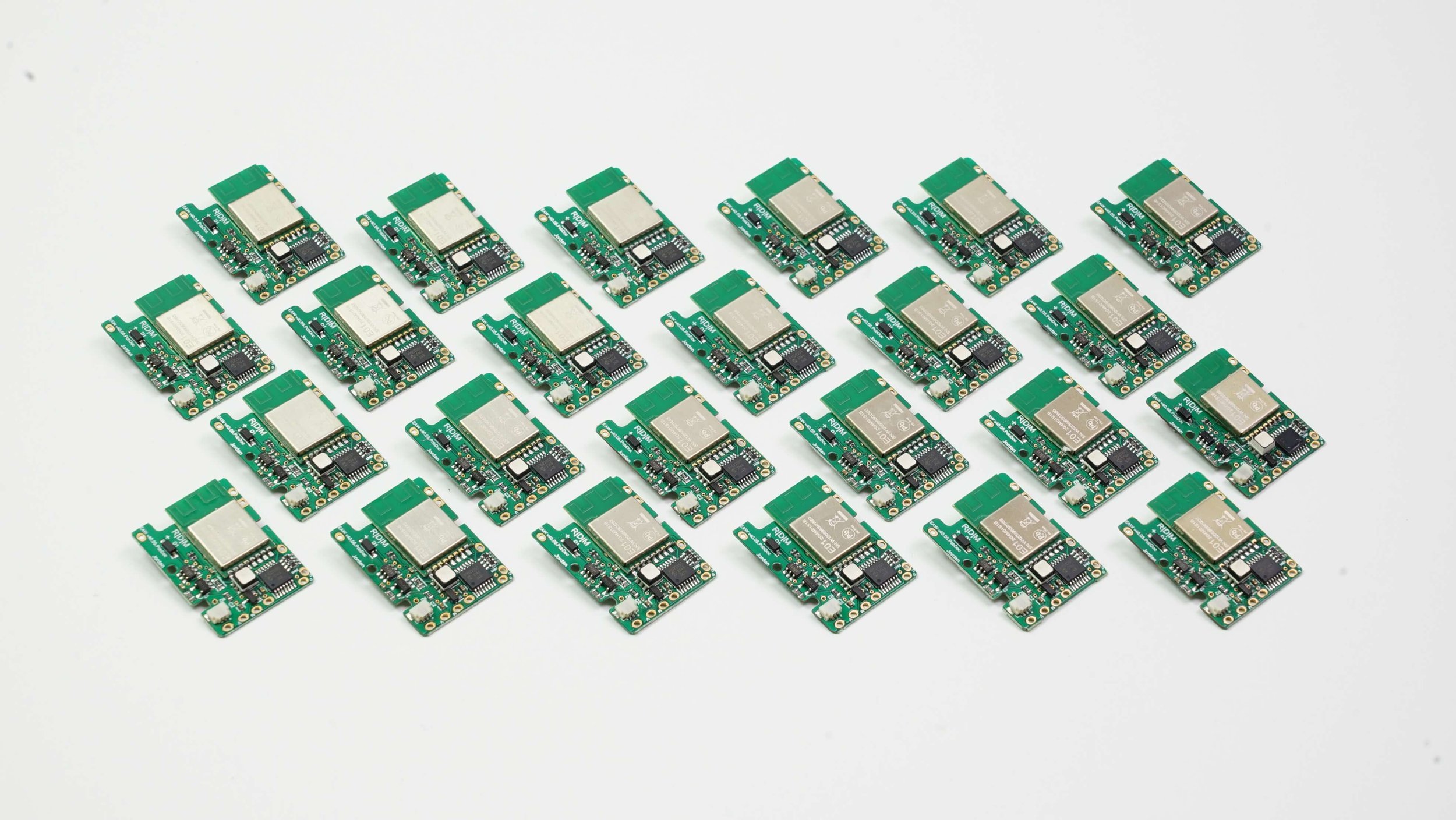

Small Batch Excellence

Even at low volumes, we maintain high standards of production. This is crucial for initial market tests, beta releases, or limited production runs where quality cannot be compromised. Whether you're producing a handful of units for testing or scaling up for initial market entry, our low rate production services are tailored to your needs without sacrificing quality.

-

Quality Assurance at Every Stage

We simulate real-world usage to verify that each unit functions as intended, ensuring reliability and performance before it reaches your customers. Our commitment to quality control means your low rate production units are as good as those produced in higher volumes. Our inspection and in-circuit testing process gives QC, agnostic of volume.