Pros and Cons of 3D Printing Techniques

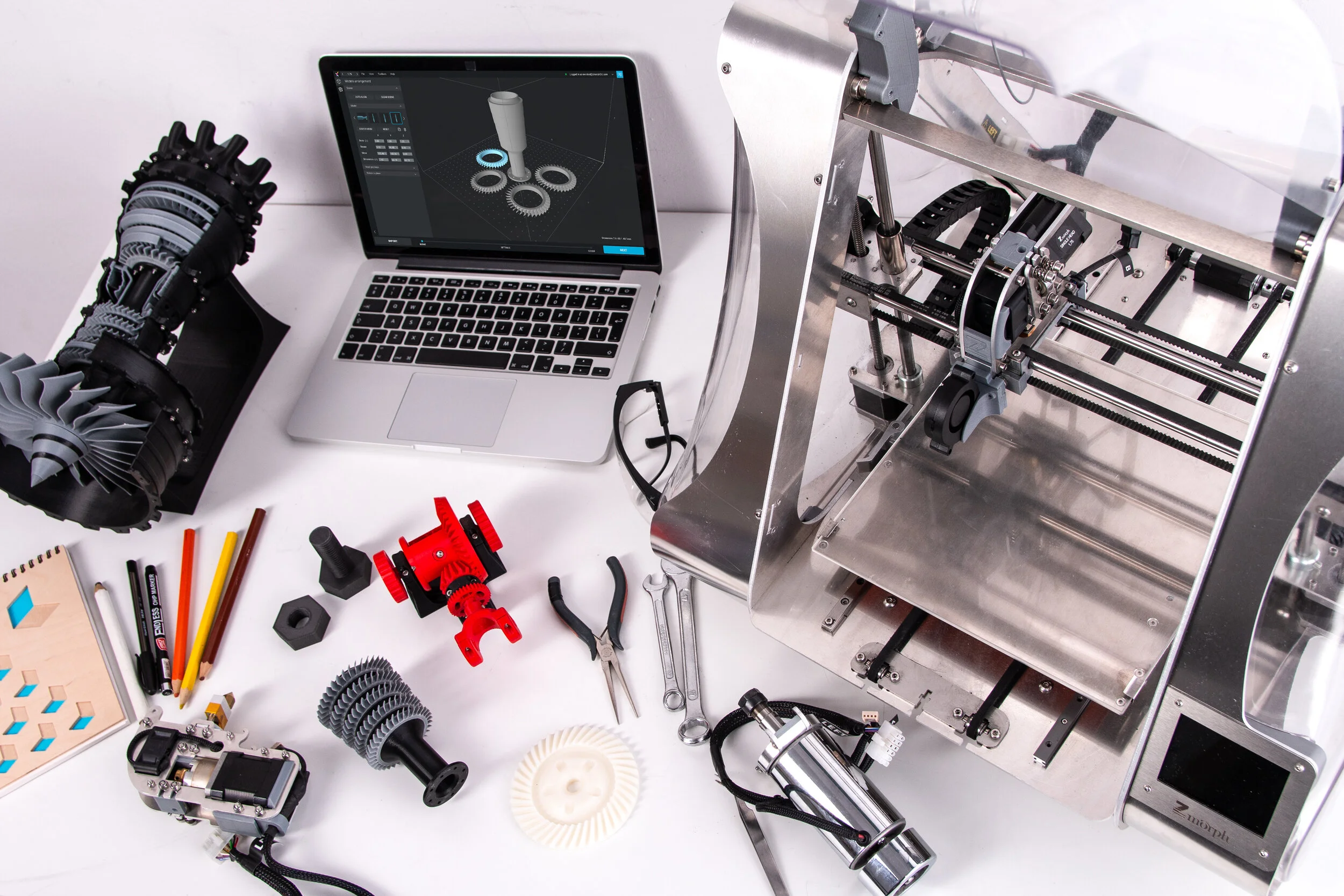

Have you ever considered creating a prototype with a 3D printer? You may want to consider the different types of 3D printers that are out there! Knowing which printer to use requires knowledge on the proper material to 3D print with. In product design, deciding if the parts need to be stiff or durable, flexible or rigid, or even production quantity and part cost all have a factor in deciding how to 3D print a product design. We’ve grown from the traditional DIY Makerbots to SLA printers and SLS printers. We see so many applications of parts and product designs with clients that need prototypes, ranging from medical instrumentation to consumer applications, so we have a wide range of experience. This article will hopefully help you decide on the method of 3D printing you decide to choose. To make it easy, here’s RDM’s list of the Pros and Cons of the three main types:

1) Fused Deposition Modeling (FDM)

a. FDM Pros: Fast, low cost, wide range of materials

b. FDM Cons: Low resolution, prone to breaking, requires support and wasted material

c. FDM Best Use: economical proof-of-concept models and large parts (by volume)

A popular choice for Proof-of-Concept prototypes, FDM printing yields lightweight and durable parts. While, limited to select materials like ABS, which is not as accurate as its SLS and SLA counterparts, FDM is a perfect match for those seeking a fast and economical solution.

2) Stereolithography (SL or SLA)

a. SLA Pros: High accuracy, high resolution, durable parts

b. SLA Cons: More expensive, limited materials, requires support

c. SLA Best Use: functional prototypes, molding**

If your components require high accuracy and excellent surface finish, SLA is a great solution. With a wide range of engineering-grade materials, the design remains unconstrained. These 3d printers and parts from SLA machines are perfect for proof-of-concept prototypes and pitch presentations/investor meetingsThe superior quality of the SLA parts comes at a higher price and typically cost more than the other 3D printing styles. Additionally, SLA 3d print times are long which will limit throughput at scale.

**molding — some engineering resins are made with inhibiting agents to plastics that are often desirable molding materials (platinum cure silicone, RTV/RTX Silicone, polyurethane, etc). Please be sure to research and perform testing before moving molds into production that were made on a SLA 3D printer.

3) Selective Laser Sintering (SLS)

a. SLS Pros: High accuracy, medium surface finish, no supports required, high through-put

b. SLS Cons: Not possible for smooth surface finish without post processing, limited materials

c. SLS Best Use: functional prototypes, production manufacturing

SLS is best suited for printing strong, functional models, which have a sandy surface finish and do not have a smooth surface like injection molded parts. This method is limited to engineering thermoplastics, specifically Nylon, and requires post-processing to achieve the desired surface finish. This post-processing is typically a combination of clearing unfused material from the build platform as well as a final bake in an oven if the model of SLS 3D printer that you are using requires it. If you are looking for high-strength, industrial-grade models, SLS is the recommended 3D printing method.

By leveraging advanced 3D printing technologies, RDM offers fast parts and prototyping with a wide selection of materials and dimensional accuracy to accommodate your needs. We use 3D models provided by you or created by us, we create built and finished parts with rapid turn-around time. In-house finishing processes seal and texture production-ready prototypes. 3D printing is an area of expertise that RDM has a great deal of experience in. If you’re looking to 3D print a prototype of your own, feel free to reach out to RDM on our “Contact Us” page to see how we can help you make your idea come to life!