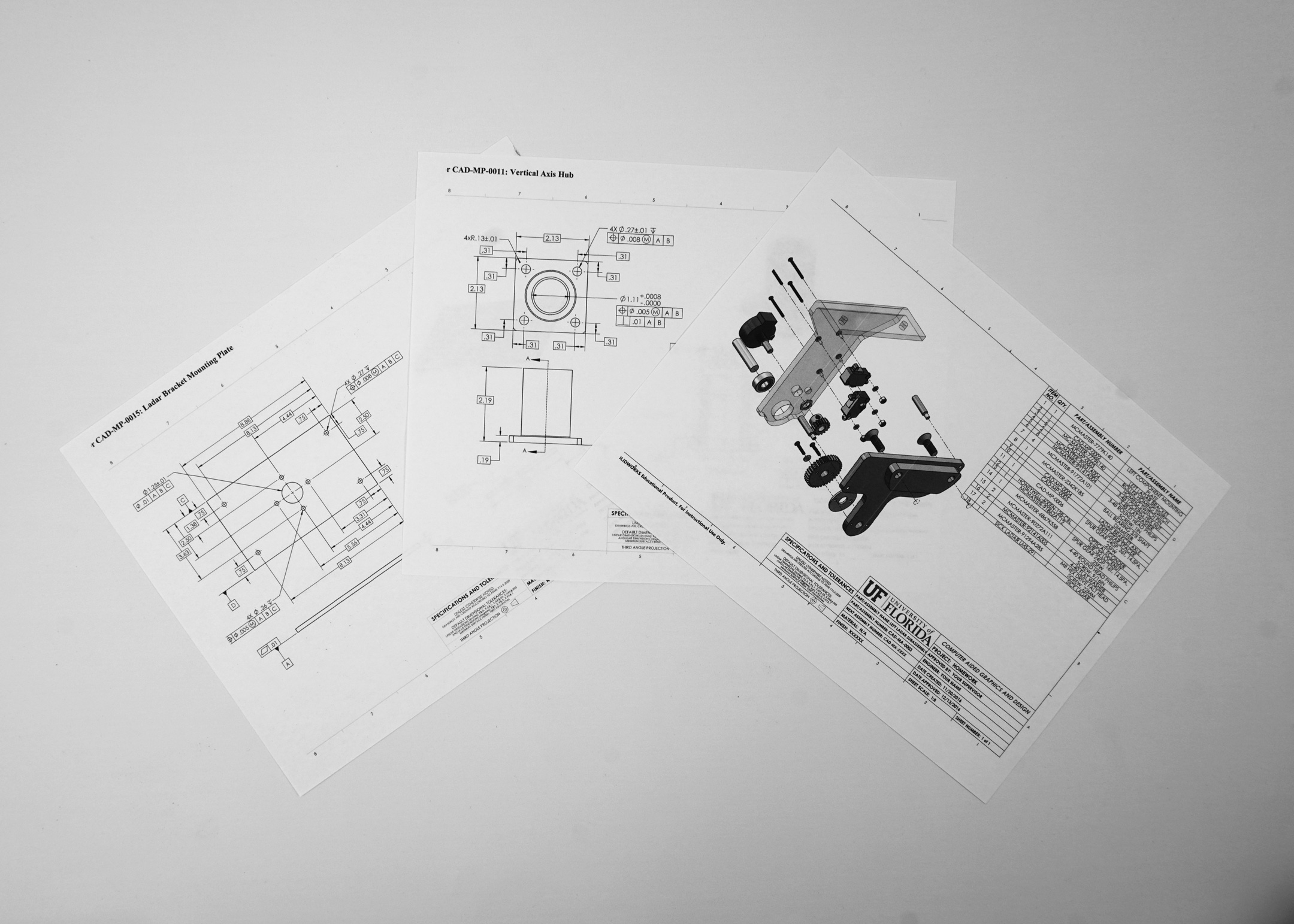

3D Modeling

Welcome to the cutting-edge of product visualization and design at RDM Innovation. Our 3D modeling services are the cornerstone of modern product development, transforming your initial ideas into detailed, functional, and aesthetically pleasing prototypes. We use advanced Computer-Aided Design (CAD) tools to ensure your project benefits from precision, innovation, and efficiency right from the start.

From Concept to Model

Start with your vision or rough sketches, and our team transforms these into 3D models using software like SolidWorks, Autodesk Inventor, and Fusion 360. We ensure every detail is captured, from the overall form to the minutest function.

Design Iteration and Refinement

The beauty of 3D modeling is the ability to iterate quickly. We simulate, test, and tweak designs in a virtual environment, allowing for multiple revisions without the cost of physical prototyping. This process is key to perfecting your product's design.

Advanced Visualization:

Beyond basic models, we offer photorealistic rendering services. This step is vital for presentations, marketing materials, or crowdfunding campaigns. See your product in various environments, colors, and finishes before it's even built.

Material and Manufacturing Considerations

We design with production in mind. Our models consider material properties, manufacturing techniques, and cost-effectiveness from the outset, ensuring that your product is not only visionary but also viable for mass production. Once your design is finalized, we provide comprehensive technical drawings and documentation. This includes all necessary views, dimensions, tolerances, and assembly instructions, ready for manufacturing.

Why Choose RDM for Your 3D Modeling Needs?

Expertise: Our team comprises CAD specialists and engineers who understand not just how to model but how to design for real-world applications and manufacturing.

Innovation: We're committed to staying on the cutting edge of 3D modeling technology, ensuring your products leverage the latest in design and simulation capabilities.

Cost and Time Efficiency: By refining designs virtually, we significantly cut down on the need for physical prototypes, reducing development costs and speeding up the time to market.

Customization: Every project is unique, and so is our approach. We tailor our services to match the complexity and specific needs of your project.

Quality Assurance: Our 3D models undergo rigorous checks for functionality, aesthetics, and manufacturability before they're considered complete.

Success Stories:

Case Study: Pressice Barware - We helped a startup visualize and refine their innovative kitchen gadget, leading to a successful Kickstarter campaign and subsequent manufacturing launch.

Case Study: EaseAlert - By employing our 3D modeling services, an established company was able to redesign a component for better performance at a lower cost, significantly improving their product line.

Let's Start Your Journey:

At RDM Innovation, your product's journey from concept to reality begins with 3D modeling. Whether you're an inventor with a new idea, a company looking to innovate, or an entrepreneur ready to launch, we're here to turn your vision into a virtual reality. Contact us today to discuss how we can elevate your next project with our 3D modeling expertise.