Product Testing and Validation

Defective or faulty designs doom products before launch and can lead to premature failure of a product once introduced to the marketplace. At RDM, we validate every product with two approaches: (1) simulation testing via modeling software and (2) application testing via custom designed test equipment. This holistic methodology allows us to identify faults, make adjustments, and validate the product prior to launch.

Simulation Testing

Using various modeling software, we perform Finite Element Analysis (FEA) on each part of your design ensuring product deficiencies are addressed before creating a functioning prototype. We are capable of simulating mechanical stress and vibration, electrostatic behavior, fluid flow, and collision motion studies.

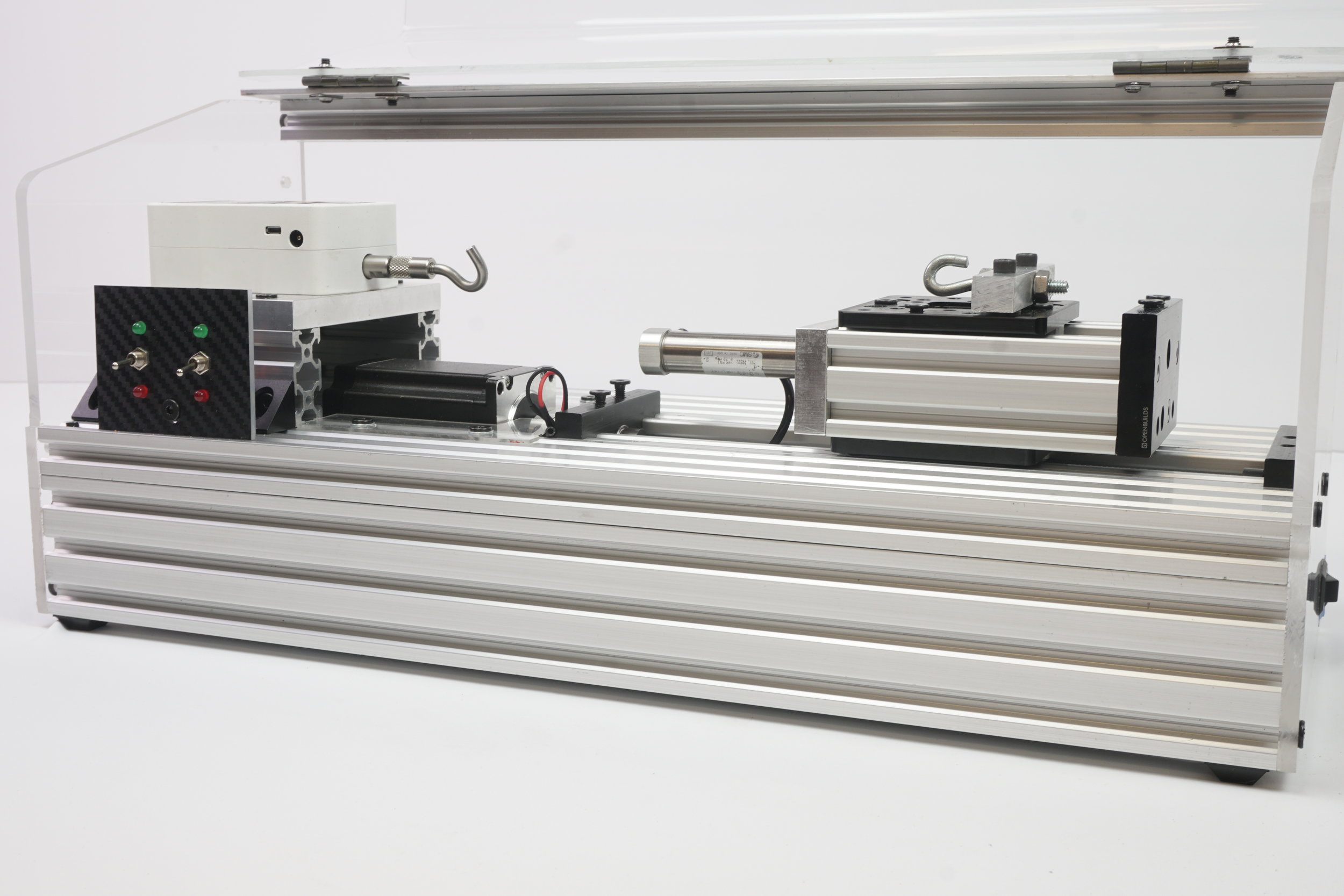

Application Testing

Products that require more than a simulation to validate functionality undergo application testing as standard operating procedure for RDM. We develop and utilize specialized equipment to test your product in a real-world like environment in order to quantifying long-term wear, limitations, and lifetime performance.